CASE STUDY: GARMO INSTRUMENTS

About GARMO INSTRUMENTS

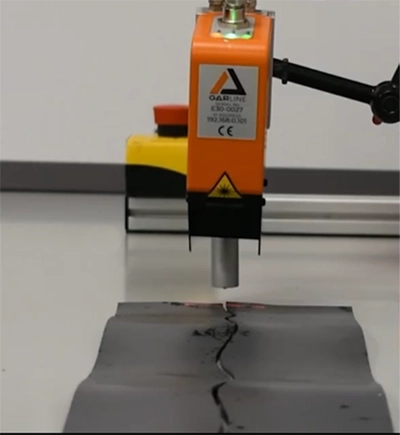

GARMO INSTRUMENTS is headquartered in Zaragoza, Spain and develops solutions for Industrial Welding automation: a Laser seam tracking welding sensor fully integrated to welding robots, cobots and PLC's. The sensor offers seam searching,

key point identification, a multiple seam library, data transmission to a welding robot or cobot through one single POE wire, seam tracking and seam teaching. GARMO INSTRUMENTS' laser sensors solve the welding issues, increase quality

levels and decrease any costs, risks or waste.

Product Background

Mongoose Web Server Library is integrated in the “GarLine” - a high-performance seam tracking laser sensor for automated welding. Where Mongoose enables secure connectivity and Web UI interface implementation.

We ran a short Q&A session with Sergio Baquedano, Engineer, GARMO INSTRUMENTS to get his feedback on working with Mongoose Web Server Library. Here are the main takeaways from it:

The challenge

Q: What challenges did you encounter that required Mongoose Web Server Library? How does Mongoose Library help you get your job done?

A: Our product is a laser welding sensor that captures frames at a very high frame rate. All these images are processed and all the data captured has to be streamed to multiple endpoints. We needed a flexible library capable of using multiple

protocols to communicate with industrial robots, PLCs, etc.; and a stable webserver to host the dashboard of the sensor. Mongoose gave us a comprehensive and flexible tool to satisfy our needs. The learning process it’s very quick

and the implementation time was very short. Once you have your hands on it it’s easy to figure out how things work on Mongoose.

The decision

Q: Can you share a little about why you chose Mongoose Web Server Library and the process that led there?

A: Before choosing Mongoose, we were testing different embedded web servers, but from our point of view, Mongoose was offering an easy-to-use and powerful tool at a minimum resource cost. In a product where every second of the process

counts to reach the speed needed, we found a fast and reliable product.

Implementation process

Q: What was it like integrating with Mongoose Web Server Library?

A: The implementation process was very quick. Once we went through the examples provided, it was very easy to have the idea of how things are done with Mongoose Library and the escalation process was effortless.

The results

Q: What changed for you after you integrated the Mongoose Web Server Library?

A: We started our work using only the standard libraries from FreeRTOS and after the implementation of Mongoose Library, everything started to grow fast. We have a stable web server running on our sensor and we are exchanging data in real-time

with devices such as PLCs, robots, a computer without any issue and in a very short implementation process.

Company

GARMO INSTRUMENTS

Launched in

Globally

Product

“GarLine” - a seam tracking laser sensor for automated welding.

Quote:

“With Mongoose Library we have a stable web server running on our sensor and we are exchanging data in real-time with devices such as PLCs, robots, a computer without any issue and in a very short implementation process. We highly recommend

Mongoose Web Server Library if you're looking for a fast, reliable, and easy-to-use tool to manage your communications. You will have plenty of examples to get started with your project development.”

Sergio Baquedano, Engineer, GARMO INSTRUMENTS

Mongoose

Mongoose